Unknown Facts About Laser Cutting Systems

Unknown Facts About Laser Cutting Systems

Blog Article

On the subject of fashionable production, the precision and effectiveness of laser cutting engineering are certainly game-transforming. Laser cutting machines have revolutionized industries by providing a way of chopping elements with unparalleled accuracy. When you’ve at any time marveled with the intricate layouts on steel or puzzled how elaborate styles are developed so seamlessly, it’s generally the work of an industrial laser slicing device.

Allow’s get started with the fundamentals: a laser cutter is actually a Software that works by using a laser beam to cut products. This beam is amazingly centered and generates higher temperatures to soften or vaporize the material, creating specific cuts. Compared with common approaches, which could use mechanical blades, a laser cutter offers a amount of accuracy that is sort of unmatched. Consider trying to carve a fragile pattern with a hammer—clearly, a laser cutter is a great deal additional refined!

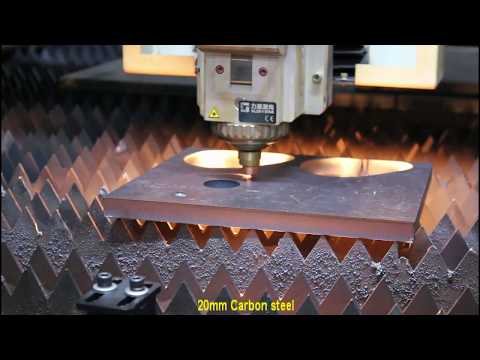

Industrial laser reducing takes this technological innovation to the next level, providing answers for big-scale operations. These machines are built to manage significant resources and higher output volumes, making sure that even quite possibly the most demanding jobs are concluded with high effectiveness. Imagine it because the distinction between using a precision knife for sensitive paper crafts and a strong saw for slicing as a result of thick wood.

The Basic Principles Of Precision Laser Cutting

In the world of CNC laser cutting, the “CNC” means Computer Numerical Regulate. This technological innovation allows for automated and highly specific cuts by pursuing electronic styles. For those who’ve at any time employed a computer to draw after which viewed that drawing come to everyday living, CNC laser slicing operates in an identical way, translating electronic patterns into Bodily cuts. It’s like having a virtual designer with the precision of the laser.

In the world of CNC laser cutting, the “CNC” means Computer Numerical Regulate. This technological innovation allows for automated and highly specific cuts by pursuing electronic styles. For those who’ve at any time employed a computer to draw after which viewed that drawing come to everyday living, CNC laser slicing operates in an identical way, translating electronic patterns into Bodily cuts. It’s like having a virtual designer with the precision of the laser.Some Known Facts About Precision Laser Cutting .

Precision laser slicing is not pretty much building cuts; it’s about creating them proper each and every time. The laser is usually adjusted to accomplish different depths and widths, guaranteeing that each Reduce is exactly where by it really should be. That is crucial for programs where even a slight deviation could lead on to substantial issues. Visualize it as a surgeon’s scalpel, in which precision is not simply important but Definitely significant.

Precision laser slicing is not pretty much building cuts; it’s about creating them proper each and every time. The laser is usually adjusted to accomplish different depths and widths, guaranteeing that each Reduce is exactly where by it really should be. That is crucial for programs where even a slight deviation could lead on to substantial issues. Visualize it as a surgeon’s scalpel, in which precision is not simply important but Definitely significant.Laser cutting devices is available in many varieties, each tailor-made to distinct requires. Whether or not You'll need a compact desktop model for interest initiatives or an enormous industrial equipment for factory use, there’s a laser chopping Answer available for you personally. These equipment range in electricity, velocity, and abilities, so it’s vital that you choose the correct just one on your certain software.

Sheet metallic laser cutters can be a Specific category of laser cutting devices developed especially for cutting metal sheets. They are really extensively Employed in industries starting from automotive to aerospace because of their capacity to tackle metal with precision and speed. Image a sheet of steel similar to a blank canvas, and the laser cutter because the artist who makes elaborate and exquisite patterns with unbelievable precision.

Laser reducing services are A different essential element of this technological know-how. Not Everybody requirements to invest in their own laser chopping equipment, particularly when they only will need occasional cuts or absence the Place for this kind of machines. Several businesses offer laser reducing companies where you can ship your styles and possess them Slash with significant precision. It’s like outsourcing your artwork to a skilled Expert.

Laser slicing devices integrate different factors to deliver the desired final results. Through the laser source to your reducing bed, and the Management computer software, each individual Section of the method is effective with each other to ensure a flawless Procedure. It’s somewhat like a symphony orchestra, the place each musician has a certain position, and only by working with each other do they develop a harmonious efficiency.

In relation to laser chopping technologies, the evolution has actually been swift and extraordinary. Initially utilized largely for slicing metals, these devices now manage check it out an array of elements including plastics, wood, as well as fabrics. This versatility helps make laser cutting technologies a important Software in many industries. Visualize possessing a Swiss Military knife that can deal with nearly any substance—This really is what fashionable laser slicing technological innovation presents.

The precision of laser slicing devices is actually impressive. They're able to Lower resources to in microns from the supposed structure, making sure that even essentially the most intricate specifics are preserved. This standard of precision is especially beneficial in industries in which exact measurements are important. Imagine it because the difference between a customized match and off-the-rack outfits—the match is simply perfect each time.

The Only Guide for Cnc Laser Cutting

One more advantage of laser chopping know-how is its efficiency. Contrary to standard slicing solutions Which may have to have a number of techniques or applications, laser slicing frequently completes the job in a single go. This not simply hastens output but also cuts down substance waste. It’s like aquiring a substantial-pace prepare that receives you towards your desired destination rapidly and effectively without any unneeded stops.In the context of industrial programs, the robustness of laser chopping equipment is very important. These devices are created to endure the needs of continual Procedure, typically jogging 24/7 in higher-quantity settings. Their longevity assures consistent efficiency and trustworthiness, which is important for maintaining production schedules. It’s like aquiring a major-responsibility truck that reliably delivers items day following working day.

One of several remarkable components of laser slicing is its capability to generate thoroughly clean and specific edges. This decreases the necessity for post-processing, which include sanding or finishing, which may be time-consuming and expensive. The end result is a smooth, concluded solution that often calls for negligible further work. Imagine finishing a craft job with no glue spills or tough edges—it’s that clean!